Ph.D in Industrial and Systems Engineering

Projects

Modeling the Anisotropic Behavior of Highly Orthotropic Polymer Separators in Lithium-Ion Batteries

Separators in commercial lithium-ion batteries are microporous polymeric films characterized by highly anisotropic mechanical behavior. An accurate characterization of their mechanical and fracture behavior is essential for optimal design, performance, and safety of lithium-ion batteries.

A monolayer Polyethylene separator was subjected to uniaxial tension and punch tests to characterize the mechanical and fracture behavior.

An anisotropic continuum damage coupled elastic-hyperelastic-viscoplastic model is developed in the framework of the large deformation theory to capture the mechanical and fracture behavior of battery separators. A robust implicit integration scheme is developed then the model is implemented as a user-defined material subroutine (UMAT) in commercial finite-element software in order to solve boundary-value problems. The capability of the proposed model to predict the anisotropic mechanical behavior up to fracture for two different types of battery separators highlights the versatility of the proposed modeling approach.

The model results showed a good agreement with the experimental data. Moreover, the model was able to predict the failure of the separators under different loading conditions.

Effect of Battery Fast Cyclic Charging on the Aging of Lithium-Ion Battery Separator

Lithium-ion batteries (LIB) are widely used in electronics devices and are the dominantly used technology in electrical vehicles. During charge and discharge, LIB undergo stresses due to the electrochemical reaction at the electrodes, causing thermal and mechanical stresses to arise in the battery components and specifically the separator. The separator plays a crucial role in the LIB preventing electrode contact and facilitating ionic transfer.

The separator aging mechanisms due to charge and discharge have been investigated under fast charging conditions. Six LIB in total were subjected to 4C charging conditions. Each pair of LIB were cycled to 400, 800, and 1600 cycles.

The physical and chemical microstructural changes in the cycled separators were investigated using a series of tests such as scanning electron micrographs, X-ray photoelectron spectroscopy, and Fourier Transform Infrared Spectroscopy. Additionally, the mechanical behavior of the as-received and aged separators was also investigated using uniaxial tensile tests and biaxial punch tests.

No chemical degradation was observed in the separator even at 1600 cycles. The main mechanism of aging in the battery separator was due to creep-fatigue caused by the battery fast charge and discharge cycling at high operational temperature.

400 Cycles

800 Cycles

1600 Cycles

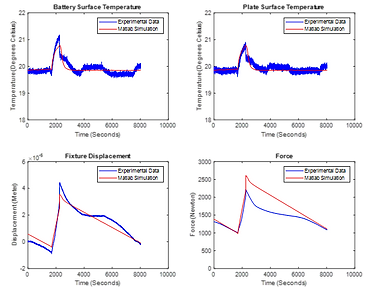

Multiphysics Modelling of a Lithium-Ion Battery Cell for Prediction of Stress Distribution in the Separator Under Fast Charge Condition

Automotive industries are quickly shifting to electrical vehicles to reduce their carbon footprint. The Lithium-ion battery is the state-of-art tool for energy storage in electrical vehicles. For wider spread of electrical vehicles, one of the main challenges is to develop safe and fast charging technologies to significantly reduce the batteries charging time while preventing any unsafe conditions such as short-circuits due to separator failure. To server this purpose, a novel battery cell model for prediction of stress distribution inside a battery pouch cell during fast charging is developed. First, a Multiphysics model is developed to predict the core temperature of the battery, the loads applied, and the displacement behavior in the battery pack array. The thermal and mechanical behavior of an NMC 622 pouch cell in a battery pack array is characterized and discussed under fast charging conditions. A robust parameter identification scheme is proposed to determine the model parameters based on experimental data. The first principal stress in the separator was shown to be around 70 MPa. Creep and fatigue tests were conducted on the separator to generate deformation damage. The results show that 70 MPa can cause significant damage in the separator after repeated fast charging.